FINISH

AVAILABLE SIZES

- 17x87.8kg / 17.09lb

- 18x88.6kg / 18.87lb

- 18x98.9kg / 19.84lb

BOLT PATTERNS

- 5x100

- 5x108

- 5x114.3

FFT – FLOW FORMing technology.

To learn more about the process visit our technology page.

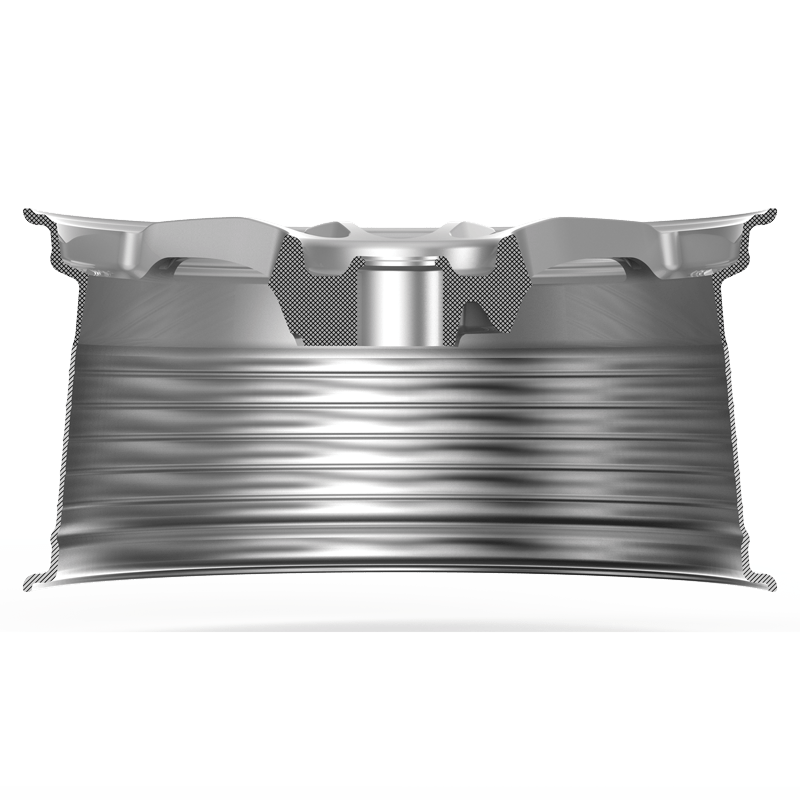

KNURLED BEAD SEAT.

DRIFZ knurled bead seat improves the grip between the tire and rim reducing tire slippage. This achieves the highest performance during extreme acceleration and deceleration.

STRUCTURAL RIDGES.

Strengthened Ribbed ridges have been designed into the barrel to benefit the structural integrity and durability of the wheel.

RACE POCKETING.

Strategic pocketing was implemented to minimize weight without compromising the strength, reliability and safety of the wheel.

FLOW FORMING PROCESS

-

PHASE 1

The Flow Forming Technology process applies extensive heat and pressure using three individual rollers to the wheel while spinning after wheel casting to begin the shaping process.

-

PHASE 2

This phase the barrel is stretched and compressed which increases tensile strength which is similar to traditional forging processes.

-

FINAL PRODUCT

The final result is a lighter, stronger wheel. This wheel has increased elongation and greater shock resistance making this a great performance wheel.